At first glance, a typical bulldozer may look unchanged from 50 years ago, but the newest models now come equipped with GPS tracking to ensure precise placement of loads and share usage data with project managers who are miles away from the job site. Definitely not your grandpa’s excavator!

The world moves fast and construction equipment is also constantly evolving and advancing. Training new employees and keeping seasoned industry pros up to speed also needs to keep pace.

EVER-EVOLVING

The International Union of Operating Engineers (IUOE) formed in 1896 and was originally called the National Union of Steam Engineers of America. It was intended to support workers who operated steam boilers, and that history is still recognized within the organization’s logo today.

As technology advanced, the union grew to encompass operators of steam-driven construction equipment, then eventually the heavy equipment we come to think of when we think of the IUOE, including cranes, loaders and pavers.

In Hawai‘i, heavy equipment operators, along with surveyors and other specialties are represented by IUOE Local 3, a chapter which also covers California, Nevada and Utah. At 40,000 members, Local 3 is the largest construction trades local in North America.

Keeping members up-to-speed is a challenge — but as the organization’s name and membership evolves, so does their training.

Aaron Tilton, IUOE Local 3 state administrator, started researching simulators in 2017, intending to replace aging PC-based simulators that had started to break down. These simulators gave users a very curtailed experience; and while rudimentary software may have simulated the mechanics of operating heavy machinery, it was still a far cry from actually being behind the controls.

A TOUGH SELL

Limitations on space and availability of equipment and personnel, along with safety and liability concerns, can make live training with actual vehicles prohibitive. While hands-on training is essential, it often doesn’t come into play until students have had practice with a simulator of some sort.

Faced with these limitations, as well as technology that was growing outdated, Tilton knew there had to be a better way. Over the next few years, he traveled to Las Vegas several times to attend ConExpo-Con/Agg, the country’s largest construction trade show, to shop for, demo and ultimately decide upon which system they wanted.

After much lobbying, Tilton was able to convince Local 3’s board of directors on the value of the simulator technology he was pursuing, and got them to approve the purchase.

THE GOODS

Local 3 decided upon the Vortex Advantage, which sits at the higher end of simulators produced by Montreal-based CM Labs.

The Advantage uses high-end graphics, an array of wide screens, realistic sounds recorded from actual job sites, proprietary algorithms and haptic feedback to make the controls and seat feel as if it’s actually moving mass and moving in space. The aim is to give as realistic an experience as possible in order to minimize any mental adjustments needed when shifting from training to real-world environments.

Once muscle memory is built up during training, users shouldn’t have to relearn the motions again on a job site. The goal is for the transition between the two environments to be relatively seamless.

Local 3 received and installed their Vortex simulator in September. While the tech is still relatively new for them, response from users has been great.

“They love it,” Tilton says of the trainees who get behind the controls. “The kids take to it, like a video game.”

The union currently uses the simulator for training of both apprentices and journeymen at all levels.

“Mostly for crane training,” says Tilton, “but also for other heavy equipment, including front-end loaders, dozers [and] excavators.”

The benefits are clear, he says. Among the upsides being that training in a controlled environment requires minimal electricity and none of the fuel or maintenance costs associated with the operation of heavy equipment.

Tilton concedes it does take a bit to get used to the software, but it’s a better experience than the union’s experiments with virtual reality (VR). He recalls a demo of a VR simulator and how it induced motion sickness in himself and others who tested it out.

That setback obviously didn’t deter Local 3 from continuing to look forward. Tilton says the union has hopes for the purchase of additional units in the future, including smaller, portable simulators designed for a variety of uses.

“Technology plays a big role in our industry. Systems like GNSS (global navigation satellite system), Total Station (an advanced surveying technology) and simulators all look to make us more efficient and therefore cost-effective,” he says.

The Vortex Advantage by CM Labs includes immersive display screens and seating, professional-grade controls and haptic feedback to give as realistic an experience as possible.

PHOTO COURTESY IUOE LOCAL 3

THE ABC’S OF TRAINING

The Associated Builders and Contractors (ABC) was founded in 1950, with the Hawai‘i chapter established in 1989. It currently represents over 170 member contractors, suppliers and service providers.

As part of its services to members, ABC Hawaii operates a state-approved trade apprenticeship program as well as safety training for member employees. Nationally, ABC’s craft training and apprenticeship programs cover more than 20 crafts; ABC Hawaii offers training in five construction trades: carpentry, electrical, plumbing, painting and roofing, while continuously seeking out crafts to maintain Hawai‘i’s workforce.

In Hawai‘i, heavy equipment operators, along with surveyors and other specialties are represented by IUOE Local 3, a chapter which also covers California, Nevada and Utah. At 40,000 members, Local 3 is the largest construction trades local in North America.

Keeping members up-to-speed is a challenge — but as the organization’s name and membership evolves, so does their training.

Aaron Tilton, IUOE Local 3 state administrator, started researching simulators in 2017, intending to replace aging PC-based simulators that had started to break down. These simulators gave users a very curtailed experience; and while rudimentary software may have simulated the mechanics of operating heavy machinery, it was still a far cry from actually being behind the controls.

Keian Shon, education director for ABC Hawaii, sees a bright future for incorporating simulators and other advancements into their training. The national organization has increasingly incorporated more modern technologies into their training programs and Shon says that “we will see an uptick in it as far as more national support in supporting these simulation programs.”

Much of ABC’s training is currently based around online training and testing, a notable upgrade from the old school pen-and-paper testing that they had once utilized.

“We can do online testing really from anywhere,” Shon says. “We do have training units outside of Honolulu, so we can monitor and evaluate as well as track through online testing as well as other types of data tracking. [That’s] the beauty of Zoom and Google Meet and [Microsoft] Teams.

“The nice thing is we no longer have to manually grade or have to manually track it. So that’s nice, really. Our online technology is based mainly around administrative support,” Shon says.

At the national level, ABC chapters on the continent are using technologies that allow users to take interactive “3-D virtual tours of tools,” according to Shon. In practice, if a student is learning how to use a drill, for example, a user of this technology would be “able to manipulate it and have a 3-D spec of it and know the functions and actually use it” without actually physically handling the tool, Shon explains.

The reduced cost of materials and liability make these virtual technologies useful on multiple levels. Shon hopes that these and other advances will make their way to the local Hawai‘i chapter in the near- and long-term.

He’s also excited about a new one-year program ABC Hawaii is piloting that’s targeted to those who are curious about a trade but not sure if it’s for them.

“It’s what we call a craft training program,” he explains. Instead of being in a classroom with 20 to 25 other students, the student will be able to learn online, at their own pace.

“It’s a really deep, really in-depth version of a classroom setting,” says Shon. “It’s almost like a one-on-one training where … this program tests them on their reading that they just did.

“It quizzes them throughout the reading, and if they get it incorrectly or whatnot, it’ll suggest where in that particular area they can look and rereview and then come back with a more in-depth answer,” he adds.

The ultimate aim is to give the student enough of an in-depth experience before fully committing to the path towards that craft.

“Instead of being on the job for eight hours a day, learning it and then just hating it after a day’s work,” they’ll be able to form and build up enough of a knowledge base to help them decide if this is for them, says Shon.

He compares the situation to the medical field, where a med student wouldn’t be thrust into a surgical setting right away; they would have the time to learn the prerequisites and develop the knowledge base before being placed in such a scenario.

“So that, in a sense, is bringing on more awareness and more interest into the field first. And that’s what we want, we want to give them the option of being interested in it,” Shon says.

“And then from there we can pick it up and get them employment and then go further into making it a career. But that’s all it’s ever been, right? You’re either going to love it or you’re going to hate it. And you have to do it first in order to love or hate it.

“But I want to say, with all of these other economic factors, we can provide the best situation for whoever at whenever. That was the mentality with introducing this program,” says Shon.

A HOLISTIC APPROACH

On Kaua‘i, Ho‘ākeolapono Trades Academy and Institute offers three programs: the High School program, focusing on students in grades 9-12; the all-female Nā Wāhine program for young adult and high school-aged females; and the Workforce program, an internship program for 17 to 24-year-olds.

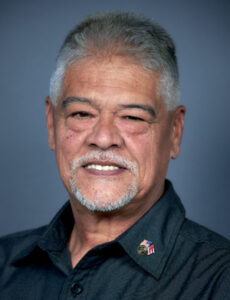

Lawai‘a Naihe, Ho‘ākeolapono founder, program director and instructor, saw a need for a construction trades program for Kaua‘i’s youth, particularly those in underserved communities. A former educator himself before entering the construction industry, Naihe intentionally set out to craft a holistic approach to teaching trades, exposing students to all facets of construction.

“I did a lot of research in starting this program and seeing in Japan, their engineers and architects, they start as laborers, they start with digging holes, picking up trash and cleaning,” he explains. “And no matter if you’re going to be a construction manager or just going to the workforce, you’ve got to start here.”

With this in mind, the training at Ho‘ākeolapono gives students a foundation that covers everything from OSHA safety certification to handling power tools to financial management. They’re given a general introduction to carpentry, electrical and other specialities, including site surveying.

Training on the latter includes the use of drones and GIS mapping tools to enhance their skill sets, with students learning to perform site surveys on random sites, often to aid the Department of Hawaiian Homelands (DHHL) and nonprofit organizations on Kaua‘i.

When DHHL was having problems with people illegally accessing property in Anahola, the school used this as a teaching opportunity — Ho‘ākeolapono students used drones to map the property and locate access points trespassers may have been using.

“The kids love to learn how to fly the drones,” says Naihe. “It’s fun.”

Moving forward, Naihe hopes to incorporate the use of more drones, as well as employing other emerging technologies in the near future.

“This year, we’re working on getting virtual reality glasses,” he says. “It’s so cool nowadays, like, you got virtual reality glasses where you can just step on a pile of dirt in the right area, and then you’d be able to stand in the middle of your house and see, like, wow, this is where the bedrooms are.

“Then we got these QR codes. You go to certain spots and you scan the code [and] it pulls up your blueprints for that specific part of the house. It gives you everything [the project is] supposed to look like.”

Incorporating these technologies into the curriculum will be expensive — Naihe estimates about $10,000 for VR and $6,000 for the QR codes — so the school will need to acquire grants to help make this possible. But it’s all worth it to provide training to the students of Ho‘ākeolapono, which he describes as a construction immersion program, with its holistic approach.

“Everything we do is … geared around construction,” says Naihe. “It makes this real learning for a lot of our kids. And it’s been working. That’s the most important part.”

PHOTO COURTESY HO‘A-KEOLAPONO TRADES ACADEMY