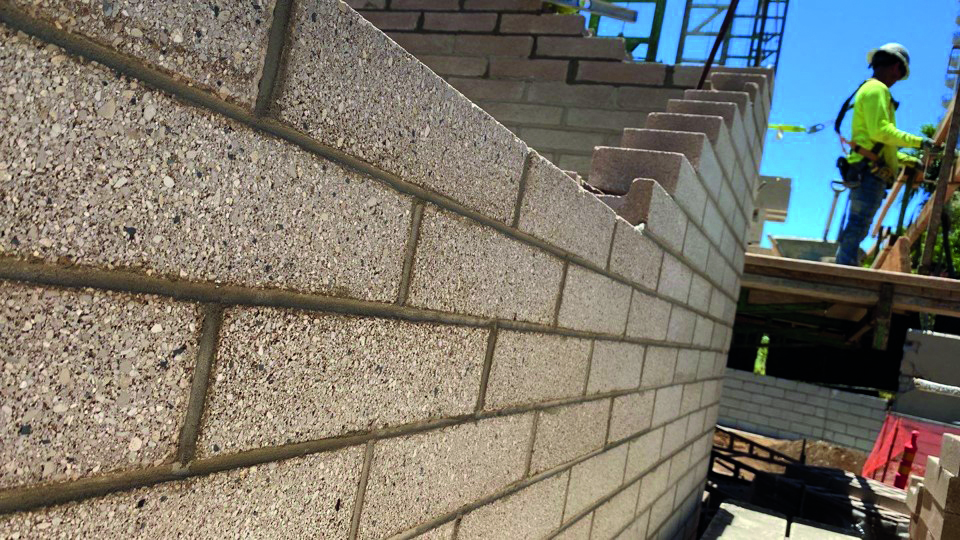

Brian Hill, president of Masonry Systems Hawaii, operates his small business with one laborer and occasional temporary hires. Last year, his crew rebuilt concrete walls and sidewalks for residential neighborhoods on Oahu; when Hill wasn’t at job sites, he managed the company’s finances and administration from his home office.

“Being a worker-owner, it’s hard to find the time to go out and find work,” says Hill, a career mason for nearly 40 years, “but I have a nice, good network of folks who call me on a regular basis.”

Brian Hill, president of Masonry Systems Hawaii, operates his small business with one laborer and occasional temporary hires. Last year, his crew rebuilt concrete walls and sidewalks for residential neighborhoods on Oahu; when Hill wasn’t at job sites, he managed the company’s finances and administration from his home office.

“Being a worker-owner, it’s hard to find the time to go out and find work,” says Hill, a career mason for nearly 40 years, “but I have a nice, good network of folks who call me on a regular basis.”

PHOTO COURTESY: Masonry Institute of Hawaii

1

Local masons are supported by local industry leaders

To ensure masons stay informed, the Masonry Institute of Hawaii (MIH) regularly hosts educational programs, including a well-attended workshop last summer by Jason Thompson, former vice president of engineering for the National Concrete Masonry Association; he introduced code-compliant new technologies and standards for concrete masonry construction.

Advocacy is another way the MIH supports local masons. An example of a policy the institute doesn’t support is the state energy code “in which our industry is advocating to not incorporate changes that will increase the cost of construction,” says Lisa Kim, director of MIH.

This year, the institute also plans to: organize tours of concrete and masonry plants; host more events and joint educational projects; and connect with more stakeholders, developers, specifiers, architects, engineers and decision-makers in construction.

2

Career advancement

for

masons is free or nominal

To ensure masons stay informed, the Masonry Institute of Hawaii (MIH) regularly hosts educational programs, including a well-attended workshop last summer by Jason Thompson, former vice president of engineering for the National Concrete Masonry Association; he introduced code-compliant new technologies and standards for concrete masonry construction.

Advocacy is another way the MIH supports local masons. An example of a policy the institute doesn’t support is the state energy code “in which our industry is advocating to not incorporate changes that will increase the cost of construction,” says Lisa Kim, director of MIH.

This year, the institute also plans to: organize tours of concrete and masonry plants; host more events and joint educational projects; and connect with more stakeholders, developers, specifiers, architects, engineers and decision-makers in construction.

Q: Masonry faces challenges, including rising cement prices and long lead times. What’s the projection for the industry in 2023?

A: “Like many of the other trades that have faced increases in the past couple of years (raw materials, commodities, gas, electricity, parts and labor, etc.), we expect the increases to stabilize. While some of these cost implications are unfortunately out of our control, there are other ways that we can control costs. Therefore, our industry advocates for reduction of unnecessary building code requirements that do not sacrifice health and safety to keep construction costs down to benefit our local communities.

Masonry is known to have short lead times due to locally sourced raw materials and locally manufactured products. However, as COVID-19 ramped up in 2020, so did production of CMU products [concrete masonry units]. Commercial construction didn’t slow down as the industry had anticipated, and homeowner projects reached an all-time high. This led to an increase in demand and longer lead times. Work has since stabilized, resulting in normalized lead times once again.”

-Lisa Kim, director, Masonry Institute of Hawaii

3

Masonry evolves with techniques and materials

Pervious concrete pavers are becoming common in masonry construction, due to new building code requirements to control stormwater runoff. Sustainable methods—stone veneer and rock walls, for example—are also on the rise, say industry leaders.

Aesthetics and design are as important as a building’s sturdiness. In 2022, Affiliated Construction LLC completed one of the largest masonry jobs on Maui: Kihei High School–Phase 2 (Kulanihakoi High School), built with integral color-ground face blocks in three different hues. The result is a unique look and solid craftsmanship that can withstand Hawaii’s natural elements.

Affiliated Construction also is building the Women’s Community Correctional Center in Waimanalo, using an insulated masonry system. It partnered with Tileco Inc. and Pacific Allied Products Ltd. to fabricate locally made foam inserts, which are placed into block walls, a method that is unique to Hawaii. And in Ewa Beach, the Hoopili residential community by D.R. Horton features ground-face masonry by Affiliated Construction.

As the building industry evolves, masonries change their services, as well. Tokunaga Masonry Inc., dba TM Construction Hawaii, was founded in 1901 as a traditional masonry of brick, block, concrete and stone. Since the company’s new ownership in 2007, TM now focuses on the repair and rehabilitation of masonry structures. It has restored several buildings including: the Neal S. Blaisdell Center; President William McKinley High School; and the YWCA in downtown Honolulu.

PHOTO COURTESY: Affiliated Construction LLC

TM’s masonry structural repairs use concrete and mortars fortified with polymer additives, says Ron Prescott, president of TM Construction. Meantime, structural reinforcement masonry structures use carbon fiber-reinforced polymer systems. “The mason skills for the application of these materials requires specialized masonry training,” he says. TM Construction has a backlog of projects for 2023 that include the McCoy Pavilion and portico at Ala Moana Park and the biomedical building at the University of Hawaii at Manoa.

PHOTO COURTESY: Affiliated Construction LLC

3

Masonry is critical for Hawaii’s construction

From the Big Island’s renovated Kona Resort to the sprawling campus of UH West Oahu in Kapolei, masonry is present in every major structure in the Islands. “Masonry is locally made, local products put together by local people,” says Karl Kamada, member-RME, of Affiliated Construction. “We’re always trying to promote masonry to developers. We’ve shown them photos of homes in California that have caught fire and the only homes left standing were the masonry homes. Would you rather have a masonry wall or wood stud wall?”

What sets masonry apart is its durability, energy-efficiency and fire-resistance compared to other building methods, such as metal frames and wood siding. “It has an exemplary life cycle cost due to its low cost of maintenance for the life of the building, making it a more economical building material overall,” Kim says.

And local masons take pride in their work’s longevity. “There is the sense of satisfaction that their projects built will outlive us all,” Kim says.