An additive manufacturing facility will soon riseon Guam, a new project envisioned to position the island as a manufacturing and training hub for U.S. Navy operators in the region.

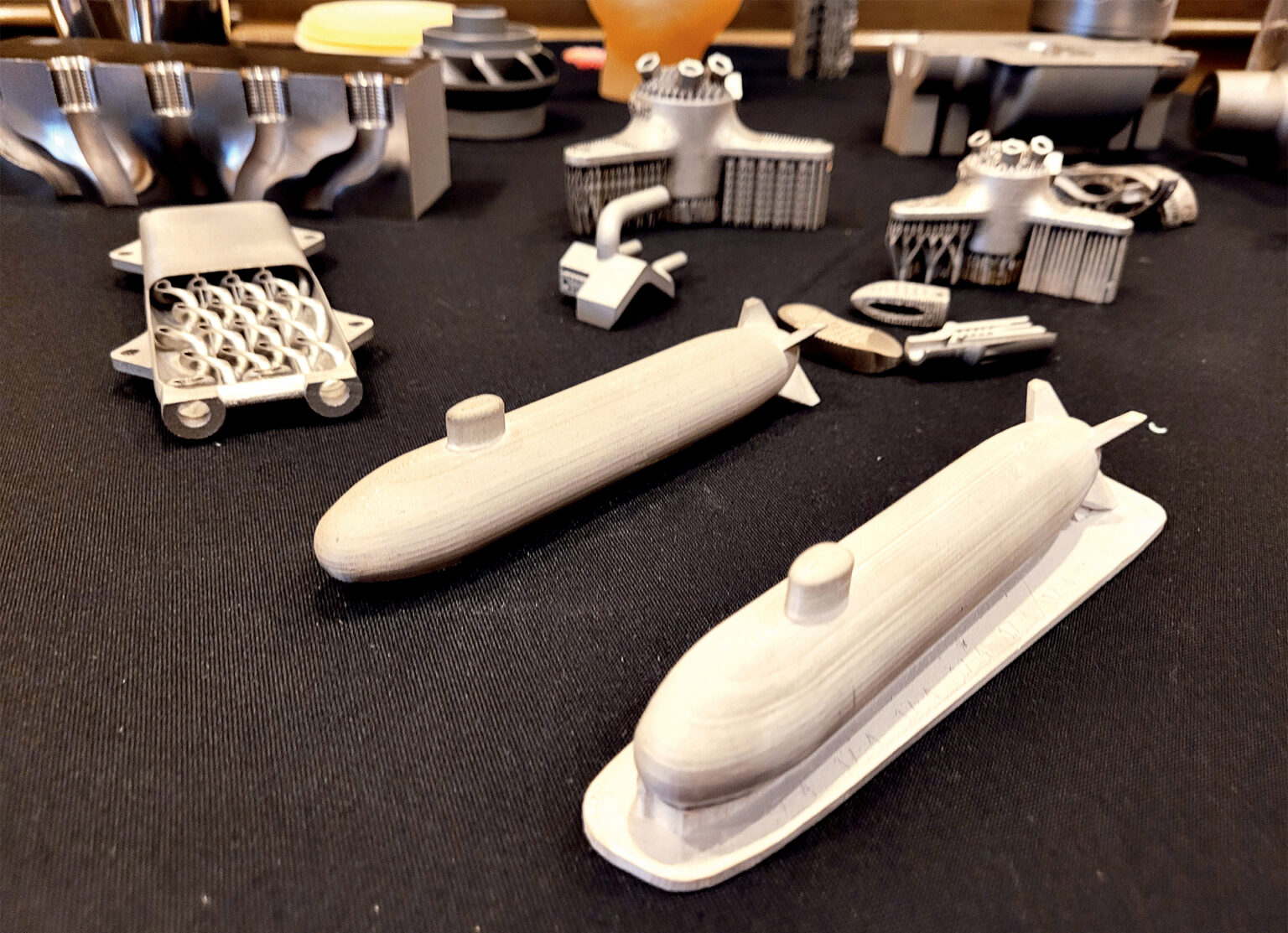

Also known as 3D printing, additive manufacturing is the Navy’s solution to challenges faced by Naval Sea Systems Command in acquiring parts and materials for submarine maintenance in the region. The lack of parts inventory results in significant delays in maintenance

service at the Navy’s public shipyards.

According to an implementation plan prepared by the Applied Science & Technology Research Organization of America, or ASTRO America, “additive manufacturing has the potential to produce parts on-demand at the point of need, consolidating supply chains, cutting lead times and significantly reducing logistical footprints.”

ASTRO America, a federally sponsored research institute and think tank, is spearheading the Guam Additive Materials & Manufacturing Accelerator, also known as

the GAMMA Initiative, which was launched in June in partnership with the government of Guam.

“Our plan is a three-year initiative to jumpstart this thing,” says Neal Orringer, president of ASTRO America. “The first stage for the first 12 months would be to start buying equipment, getting a temporary facility going, and getting folks from Colorado School of Mines to start the training here.”

NEW PARTNERSHIPS

ASTRO America and the government of Guam have agreed to build a $16 million temporary facility at the University of Guam that will serve as a satellite campus for the Colorado School of Mines.

“Hopefully, by the end of the calendar year — but certainly by the end of Q1 of 2025 — we can get that going,” Oringer says. “Then in the next two years, we would like to start understanding the demand. We are going to work with the Navy folks here to see if there are actual parts that they need us to demonstrate so that we can actually build parts.”

ASTRO has also teamed up with the Blue Forge Alliance, a Texas-based organization that supports the Navy’s submarine industrial base to sustain the maritime manufacturing sector. Blue Forge is funding the pre-planning stage, including the purchase of equipment.

“These machines are not cheap. The 3D printers typically run from $1 million to $5 million per machine. These are metal, very heavy industrial machines,” Oringer says. “It will take a long time to actually put orders in and to start purchasing, so we need to get started as soon as possible.”

Blue Forge also sponsored trips for the first two groups of Guam Community College students who were sent to the Navy’s advanced manufacturing training center in Virginia and the Colorado School of Mines for a 16-week program to begin the development of a talent pipeline.

“Many of the initial highly technical positions will necessarily need to be filled by hires [from the U.S.],” Orringer says. “In these cases, ASTRO intends to prioritize hiring personnel who have interest in establishing permanent, long-term roots in Guam.”

Once up and running, the facility is anticipated to generate 85 to 100 new jobs.

DEVELOPING A PIPELINE

“Our participation in this project is to identify and develop the pipeline that can help support the workforce needed for additive manufacturing,” says Mary Okada, president of Guam Community College.

Okada says the college is currently seeking to establish a plan to tap the high school population in preparation for post-secondary courses and ultimately a degree path. The plan will involve the development of a pertinent curriculum in collaboration with the Colorado School of Mines.

GCC will pilot a program for high school students who may be interested in pursuing a career in 3D printing. “Right now, we’re gathering information as to what is necessary so we could establish a pilot program,” Okada says.

Orringer says the initial funding will also cover the cost of hiring faculty and staff, teaching and research. “I think there are a lot of opportunities here for us to co-invest in a project that’s going to, hopefully, have a lot of returns on investment for many years to come,” he says.

THE CIVILIAN SECTOR

In the civilian sector, one Guam-based company has identified 3D printing as a potential solution to the island’s housing shortage.

“When most people hear the term 3D printing, they think of small-scale printers using plastics or metals. But imagine scaling that up to print entire houses using concrete,” Ann Dela Cruz, co-founder of Stars and Technologies, said during the ninth Assembly of Planners’ Symposium at the Hyatt Regency Guam on Aug. 9. “This technology can be faster, better and cheaper. It’s faster because it prints continuously, better because it uses durable concrete and cheaper because it reduces the need for skilled labor and minimizes material waste.”

According to ASTRO America’s implementation plan, the 3D printing facility on Guam will also support the United States’ commitments to the AUKUS treaty, “which seeks the integration of security and defense-related technology, industrial bases and supply chains of Australia, the United Kingdom and the United States.”

“With some of the Department of Defense’s urgent needs and Guam’s geopolitical importance, we think there could be a really interesting synergy between academia, industry and government to create a new ecosystem,” Orringer says.

“It’s going to take a lot, and there are a lot of long lead items. If we want to be able to meet the production capacity that we believe could eventually be here, we’re going have to start ramping up and building up that capability.”